How to solder

Mô tả của How to solder

How to solder

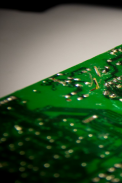

How to properly solder The first thing that needs to be done is to prepare everything necessary for soldering: a soldering iron, a small sponge, solder, pliers or tweezers, side cutters.

Turn the soldering iron into a power outlet and moisten a sponge with water. When the soldering iron heats up and begins to melt the solder, coat the tip of the soldering iron with solder, and then wipe it on a wet sponge. Do not hold the sting in contact with the sponge for too long in order not to overcool it.

Method of teaching rations

If you have never soldered, we suggest using one of two methods, which are based on practice, as in any other method.

Basic soldering rules

When soldering a few rules must be followed, then the soldering will be reliable and accurate. It is best to use solders POS-61, POS-50, POS-40 and alcohol-rosin fluxes, it is necessary to heat the junction to such a temperature so that the solder attached to it can melt.

The solder should melt due to the heat given off by the junction, the junction should be carefully cleaned, the junction should be fixed until the molten solder hardens, do not overheat the junction, solder should not be too small, solder should not be too much.

Useful tips and observations

Soldering is not the solder solder, like tar or cement, on the parts being joined. This is the process of soldering into the micro gaps due to capillary phenomena and adhesion (sticking) of the solder due to surface phenomena. All these are electrostatic forces, although this is not your usual electrostatics, these are forces of intermolecular interaction at close distances. And here you need to clearly remember how the phenomena of wetting and capillarity work.